* They can be used with epoxy resin, resin and wood, concrete, plaster and more.

* They never need assembled, or disassembled. Saving huge amounts of time.

* The strength and flexibility of the molds allows you to insert and remove pieces of wood easily.

* The corners and edges never need sealed.

* When using wood, the wood stays in place, tight in the mold if you cut it 1/16" larger than the width of the mold. Preventing the need for clamps or weights.

* The mold is heat resistant (within reason!), and wont damage when you are popping epoxy bubbles with a torch or heat gun.

* The molds are reusable. However silicone molds do have a finite lifespan when used with epoxy resin, but getting 20-30+

castings out of the mold can be expected when they are properly cared for and a mold release spray is used.

* Like HDPE, epoxy does not stick to silicone. However in rare cases where the epoxy hasn't fully set (and is still mildly tacky) it can be harder to remove, and potentially create pits or small tears inside the mold when your piece is pulled out. Thus, we recommend the use of mold release spray before each pour to increase the life of your mold.

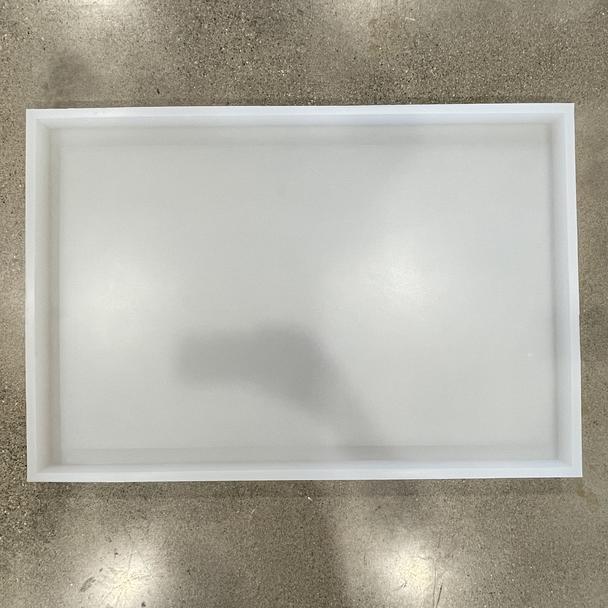

Thick large silicone/HDPE Molds

Silicone Mold For Epoxy Resin-Cheese Board & Cribbage Board Form Table Top Bar Customize size

- Customize logo

- Customize size

- Customize packaging

- Sample support

- Product description: Our silicone mold adopts advanced technology and is made of high-quality clear and durable silicone. It is thick and soft. The silicone is flexible, durable, and does not require a release agent,

Silicone Mold For Epoxy Resin - Cheese Board & Cribbage Board Form Table Top Bar Customize size

Features

A popular mold amongst resin artists. You can easily create beautiful surfboard shaped beach and ocean scenes using rocks, sea shells and waves. You can now create true layers with incredible visual depth and detail thanks to this mold.

Like all of our silicone molds, this mold features super thick sidewalls and bottom to reduce the likelihood of it warping during your pour.

DIY Pleasure

Enjoy life, enjoy DIY. We can use it to make any exquisite artwork we like with dried flowers,pigment or any other materials. To make our life and mood more interesting and more beautiful!

It's amazing!

Enjoy life, enjoy DIY. We can use it to make any exquisite artwork we like with dried flowers,pigment or any other materials. To make our life and mood more interesting and more beautiful!

It's amazing!

Product Description

|

*Product category

|

Surfboard Silicone Mold

|

|

*Texture of material

|

Silicone

|

|

*Shape

|

Rectangle

|

|

*Application

|

DIY Resin Mold

|

|

*Sample

|

Support

|

|

*Specifications

|

Table Top Bar Customize size

|

|

*Payment method

|

Trade Assurance, PayPal, T/T, Credit Card, Western Union

|

|

*Mode Of Transport

|

FOB/CIF/ EXW/ DDP /FedEX/ UPS etc.

|

Tips:Any color and size can be customized.

The last mold you will ever need. Created just for makers, resin artists and wood workers, these time saving flexible yet durable silicone molds significantly cut down on the setup and demolding time usually involved with other molds. Silicone molds are superior to wood and tuck tape, and HDPE molds because:

Product Packaging

We provided high-quality opp bags for each product.

And customized high-quality export cartons according to customers requirements.

We provided high-quality opp bags for each product.

And customized high-quality export cartons according to customers requirements.

Mode Of Transport

Mode Of Transport

Categories

Latest News

Contact Us

Contact: Jacos

Phone: +86 13788827392

Tel: +86 13788827392

Add: JiaBao, BeiQing District, Fujian Province, 361000

order@diyulove.com

order@diyulove.com